Nature can not collect hydrogen directly. However, modern technologies enable us to make hydrogen in the following three major ways.

Steam reforming (SR) process:

The feedstock for this process is natural gas. First, natural gas goes through desulphurization process to prevent catalyst poisoning. Second, the natural gas mixed with water steam enters in a reactor called reformer at very high temperature (700-1100 °C). The reformer will produce a mixture of hydrogen and carbon monoxide. We often call such mixture as syngas. Third, the syngas mixture enters into a water gas shift (WGS) reactor. Carbon monoxide further reacts with water steam at low temperature (300-400 °C) to produce more hydrogen. The WGS reactor also produces carbon dioxide as by-product. Finally, hydrogen goes through the pressure swing adsorption (PSA) step to remove the unneeded carbon dioxide. In this process, every ton of hydrogen produced also generates twelve tons of CO2, one of greenhouse gases to be released into the environment.

Water electrolysis:

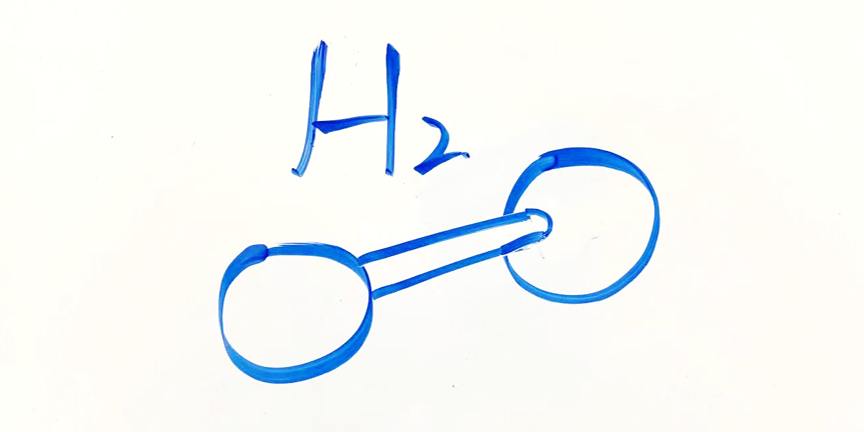

Pure water is the feedstock for this process. First water enters into a reactor called electrolyzer. In electrolyzer, electricity split water molecule into hydrogen and oxygen gases. We can then collect hydrogen gas from an outlet at cathode side, and further dry it through a dryer. On the other hand, we can collect oxygen from the anode outlet, or simply release it to the air if not needed. If we power the electrolyzer by electricity from renewable resources, such as solar, wind or hydro energy, the entire process should release zero carbon therefore has numerous emission benefits.

Biomass fermentation:

In this process, biomass is the feedstock and enters into a bioreactor, where bacteria consume it and produce hydrogen and carbon dioxide mixture at ambient temperature and pressure. The mixture then goes through a separation step so we can collect the pure hydrogen at the end. Again, this process release considerable amount of CO2 into the environment.